Grolsch Top Ceramic Bottle

|

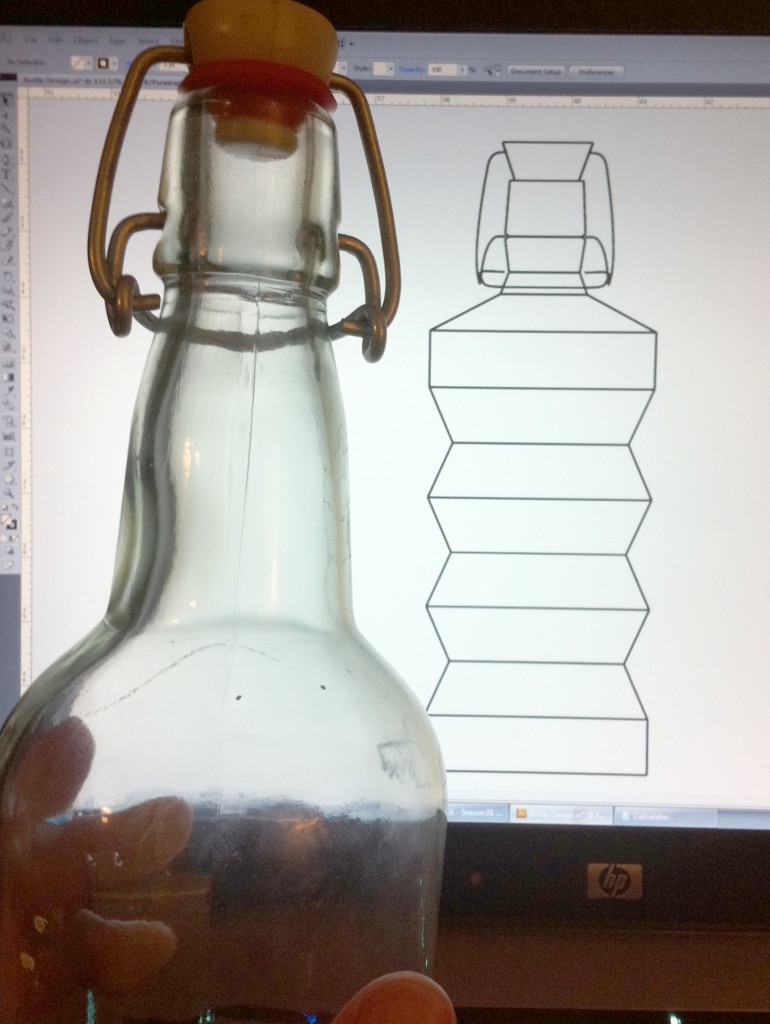

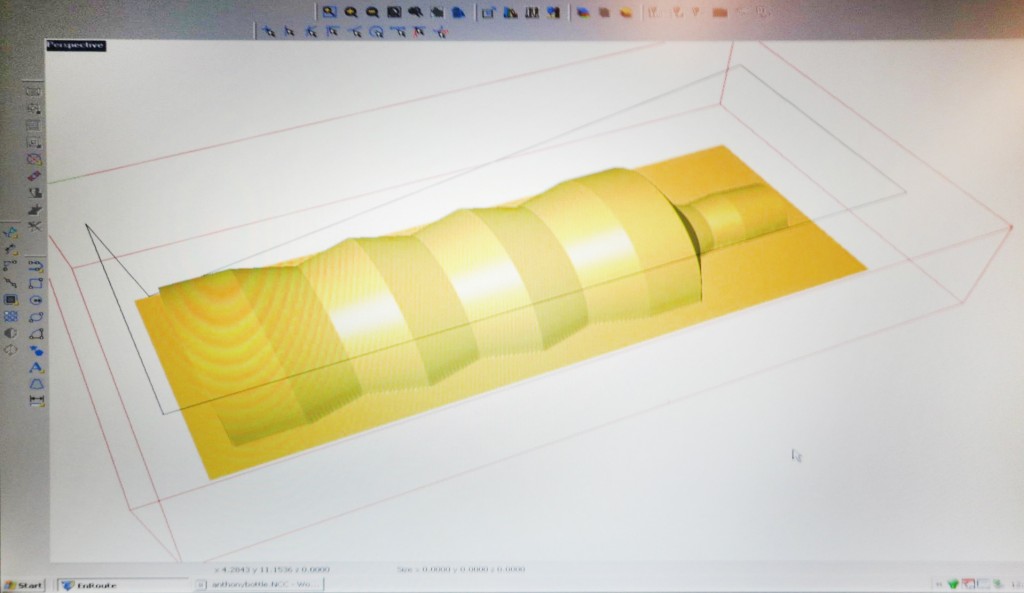

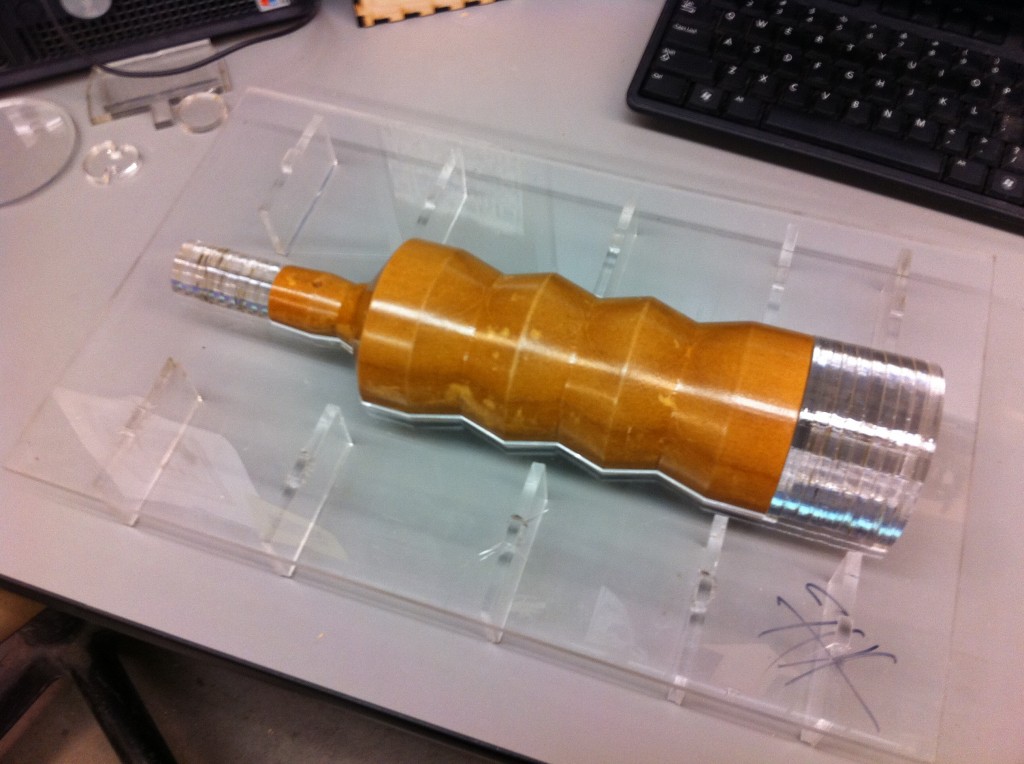

During this summer one of my goals was to design a positive model in a three dimensional modeling program and then have it routed out with a CNC Machine. This worked perfectly with my desire to make a ceramic bottle that utilizes a Grolsch lid. Because I wanted to utilize a Grolsch my model had to have very precise dimensions, which computer modeling and CNC routing afforded. For the beginning of the design process I took an existing glass bottle and used a digital caliper to get the dimensions for the wire fittings of the lid. From there I incorporated those dimensions into Illustrator to create a rendering the bottles profile. The rendering from Illustrator was exported as an .eps where the profile of the bottle was revolved to create the three dimensional computer model. The router then milled the file twice to create the two halves of the bottle. This image shows how the CNC machine utilized several tool paths to clear material and then mill a smooth surface. This image shows how the two parts fit together. The next step will be to glue, sand and polyurethane the positive model and then create a plaster mold off of it for slip casting.

*UPDATE After sanding and applying polyurethane to the positive I decided to take the digital fabrication of my mold a step further. I created a divider where the part lines of the mold would be with laser cut acrylic. Traditionally this would be done with clay but I figured since the positive was digitally fabricated I could utilize that precision to create a divider that was not only more crisp and accurate but would also afford for reuse, if I should decide to cast another mold off of it. Here is the positive mold in a cottle box with the laser cut acrylic divider. First half of the mold. The two parts and pedestal. Here is the first cast greenware piece from the mold. I am very pleased with the precision achieved from the combined digital processes and looking forward to posting some pictures of the finished piece. |