MacBook Pro

|

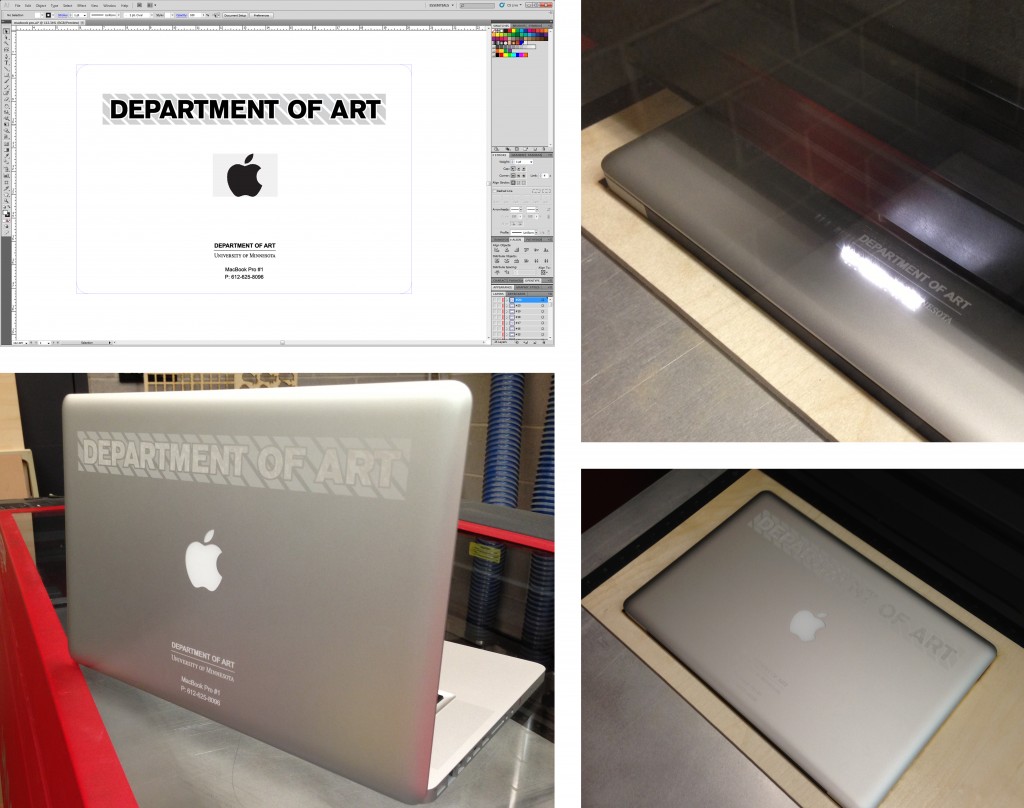

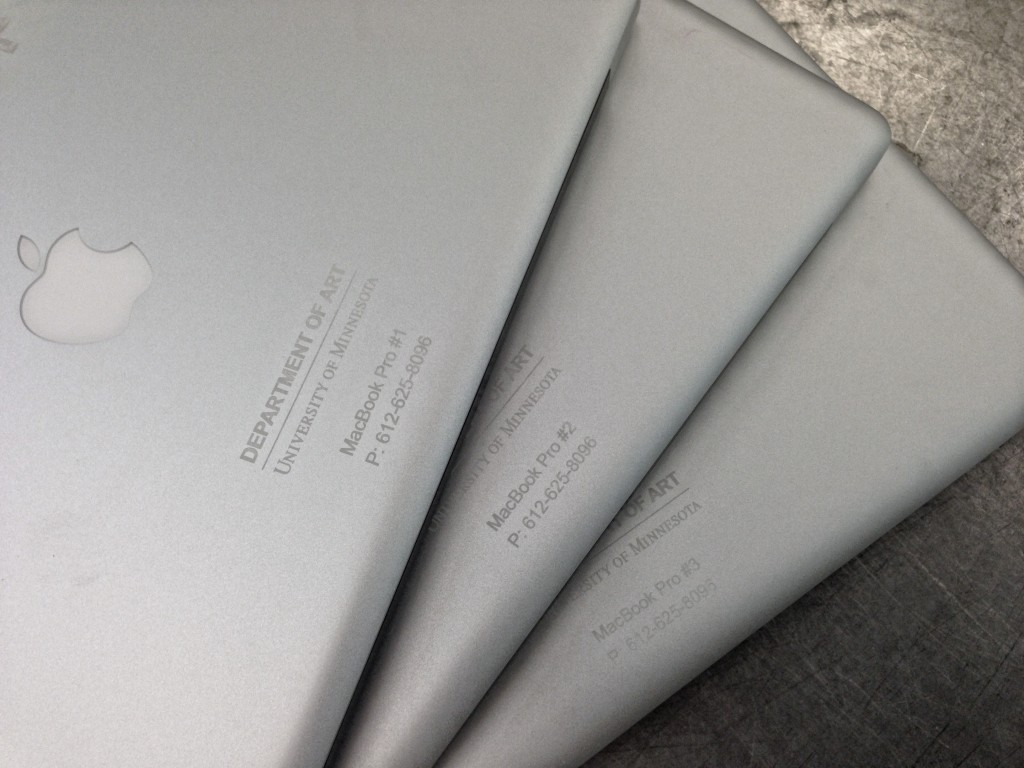

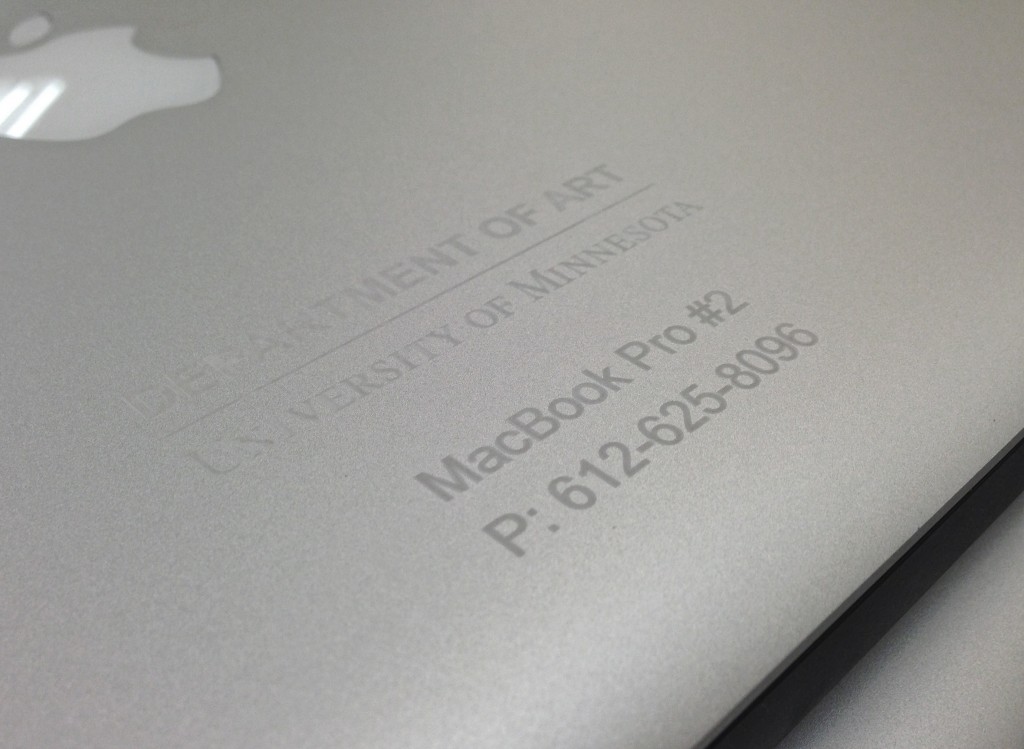

As part of my job as the laser cutter technician for the University of Minnesota’s Department of Art I was recently asked to etch a crop of new MacBooks for the department. I was asked to place some sort of graphic on them that would make it obvious that you were using department property (thus deterring theft), so I used the newly created department logo. Additionally unique numbers were etched on to each machine for inventory identification and a contact phone number was added if the property were to be lost. To place this information I created a template in Adobe Illustrator that accounted for the placement of the Apple logo and overall dimensions. I also laser cut a wooden jig to place the laptops in as I had 21 of them to do and wanted to expedite the process. The laser cutter creates value via halftone and as the department logo has two different values I had to do some testing on the bottom of the first MackBook to get good tonal contrast. This image shows the difference between the 100% black text and the highly tinted diagonal bars behind the text. From my understanding when anodized aluminum is etched you are removing trapped ink from the surface of the subject. Since the anodized layer is so thin and because you are just removing ink there is not a lot of power required to create a mark on your material. For an exquisite explanation of the anodization process view this YouTube video created by Bill Hammack the Engineer Guy. Lastly an interesting property that I observed, of the etched anodized aluminum, is the value shifting that occurs when viewing a marked surface from different angles. The image above and the one below demonstrate this change (as best can be shown in a photo). |